The television crew from 60 Minutes Australia was top notch, efficient and organized, professional and quick. One of countless media outlets from around the world that descended on West Virginia University’s campus, they sought to tell a “David versus Goliath” story — pitting a small laboratory at WVU against the No. 1 car maker in the world. But for WVU’s researchers there was always more to the story.

For Dan Carder, a self-proclaimed engineering nerd from Parkersburg, W.Va., the media circus that has surrounded the work of WVU’s Center for Alternative Fuels, Engines and Emissions, or CAFEE, over the past seven-plus months has been entirely surreal.

“When I became an engineer 25 years ago, I never thought the general public would be interested in this kind of research,” said Carder, who has been director of the center since 2010. “I certainly never thought I’d get a phone call from Leonardo DiCaprio’s ‘people,’” he said in reference to the actor’s intent to produce a feature film about the U.S. Environmental Protection Agency’s discovery that Volkswagen had been cheating on emissions tests.

“We’re probably the last people you would want as spokespeople,” he laughs. “We spend most of our time in the lab or in the field working on equipment or analyzing data.”

But he and the rest of the five-person team whose research on real-world diesel emissions revealed data that broke open the Volkswagen scandal have taken the attention in stride — even though their newfound media responsibilities have usurped more quality lab hours than they would prefer.

Their unceasing dedication to their work was apparent two-and-a-half years ago when Marc Besch, Arvind Thiruvengadam and Hemanth Kappanna — all graduate students at the time — alternated 16-hour shifts to drive three test vehicles around southern California and up to Seattle.

In 2013, CAFEE contracted with the International Council on Clean Transportation, an independent research group, to conduct a small $70,000 study on emissions levels from diesel passenger vehicles in the United States.

The council reasoned that because the U.S. had the most stringent emissions standards in the world, diesel cars in the U.S. market would have to be ultraclean. Basically, they set out to prove that if diesels could make it here they could make it anywhere.

"The happiest moments for us aren’t related to anything in the news. They are when we find out that our research has made a change.” - ARVIND THIRUVENGADAM

REVEALED ON THE ROAD

Spoiler alert: They were wrong. (Well, not entirely, but more on that later.)

After the International Council on Clean Transportation presented the results of the WVU study to the EPA and the California Air Resources Board, the regulatory agencies did some digging of their own. Eventually, Volkswagen admitted that their diesel vehicles employed a “defeat device” — complex instructions coded in the car’s computer-controlled brain that turned on emissions control technologies during compliance tests in the laboratory and then turned them off during real-world driving situations. Outside of the lab, cars were spewing up to 35 times more oxides of nitrogen than allowed by regulatory standards.

When WVU began the study, government regulators only performed compliance tests in a lab setting on a chassis dynamometer — basically a treadmill for cars. They did not have compliance tests for diesel passenger vehicles out on the road, but the EPA says that will change soon.

“Car makers know exactly how they are going to be evaluated by regulators,” Carder said. “It’s like giving a student all the questions to a test before the student takes the test."

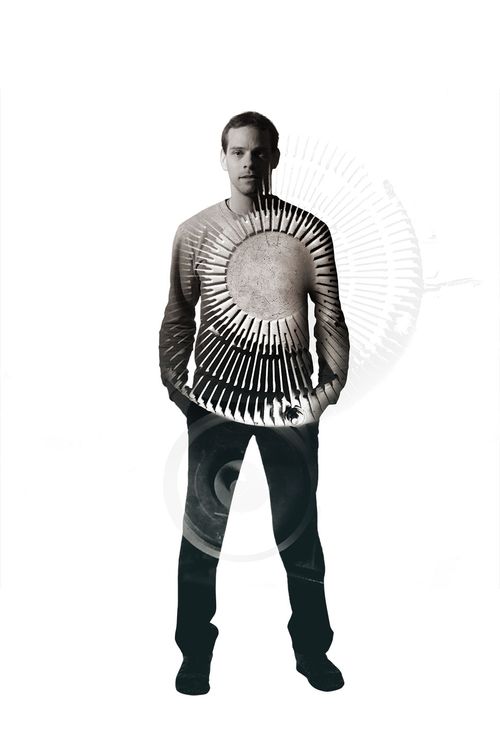

Marc Besch

Marc Besch

In addition to a lack of real-world testing, there wasn’t much publicly available data on diesel emissions from passenger cars.

For WVU’s engineers, that was enough to pique their interest.

It may come as a surprise to non-gearheads that anyone in the U.S. drives a diesel vehicle these days. In the 1980s diesels had a near disastrous introduction into the American market, embodying the stereotype of a noisy, dirty and slow mode of transportation.

But modern clean-diesel technology is nothing like its soot-covered cousin of the past. The engines are powerful, offering lots of torque — the twisting force that gets you from zero to 60 faster. They also have longer range and higher fuel economy than most gasoline vehicles. Most importantly, they feature technology that cleans the vehicle exhaust that once soiled diesel’s reputation, but only if the technology is implemented properly.

WVU’s team proposed a study in which they would test three of these clean diesel vehicles on driving routes between Morgantown, Washington, D.C., and Florida. The make and model didn’t matter, but they had to have diesel engines, fewer than 120,000 miles on the odometer and not be brand new.

There was one snag. They couldn’t find any vehicles to test.

The team quickly realized that with the limited percentage of light-duty diesel vehicles in the U.S. market, most rental agencies didn’t carry diesel cars on their lots.

So the team turned its attention nearly 2,500 miles west to southern California, where they were already conducting research projects — and, as Thiruvengadam says, “the weather was better and fish tacos were nearby.”

Years of strict emissions regulations in California had pushed car buyers in the state to be more progressive with automotive technology, so diesel vehicles were more prevalent. In the greater Los Angeles area, the team found three vehicles from two commercial rental agencies and a private owner — a Volkswagen Jetta, a Volkswagen Passat and a BMW X5.

“The availability of vehicles drove a lot of what we were able to do,” Carder said. “Looking back, had we been able to find vehicles on the East Coast, this story might have had a different ending.”

It turns out, Volkswagen’s secret was 2,450 miles away from never being discovered.

“Finding the Volkswagen vehicles was very interesting for us as engineers,” said Besch, who is completing his PhD and working as a research assistant at CAFEE. “Volkswagen was the only vehicle manufacturer to use the two types of diesel after-treatment systems, and the vehicles had the same engine. So, from a research standpoint, it was favorable to be able to compare the two.”

All three vehicles featured high-tech “exhaust scrubbing” systems that are very efficient at ridding vehicle exhaust of dangerous substances such as oxides of nitrogen that contribute to the creation of ozone. They have the ability to reduce pollutants from 1,000 parts per million to under 10 parts per million at the tailpipe.

The Jetta featured lean-NOx trap technology, while the Passat and the BMW X5 had selective catalytic reduction systems.

“We have been working with these control technologies for decades in the heavy-duty market,” said Greg Thompson, associate professor of mechanical engineering and principal investigator of the study. “So, we are conversant with performance characteristics of these control strategies and how well they can perform on the road.”

In fact, for Thompson, Carder and Kappanna, the experience with Volkswagen was eerily familiar to work that they led in a landmark settlement between the EPA and a group of heavy-duty engine manufacturers — companies that make engines for commercial trucks and buses.

DEJA VU ALL OVER AGAIN

At CAFEE’s on-campus laboratory, a 10,000-pound behemoth and three of its engine brethren waited for instructions. The room teemed with their coiled, tentacle-like cords and tubes, reaching across the floor and climbing into the ceiling like jungle vines escaping the darkness of the forest floor. The beasts were still, their growls silenced. After a few minutes they began to roar as their breath was captured in a maze of tunnels overhead.

In the late 1990s, U.S. environmental regulatory agencies found that engines from six heavy-duty diesel engine manufacturers used software that made the engines perform differently when being tested in a laboratory versus on the road. The software caused the engines to switch to a more fuel-efficient driving mode — but with higher oxides of nitrogen emissions.

Unlike Volkswagen, the heavy-duty manufacturers claimed the use of the software was a misunderstanding with regulators and was never meant to intentionally undermine compliance standards.

“It was almost unbelievable to see such a similar thing happen again,” Besch said.

“When we saw the news of what Volkswagen had done, we were as shocked as the rest of the world,” said Thiruvengadam, who is now an assistant professor of mechanical engineering at WVU. “To this day, we are still surprised.”

Eventually, in a historic settlement, the EPA fined the heavy-duty engine manufacturers $1 billion and required them to conduct real-world pollution research and to upgrade their existing engines in order to lower emissions.

Because of their expertise, CAFEE was called on to work with the manufacturers to develop the world’s first mobile emissions measurement system designed to provide accurate diesel emissions measurements while withstanding the shock and vibration encountered in on-road testing.

Their work resulted in the development of current emissions compliance standards for heavy-duty engines and the subsequent commercial development of portable emissions measurement systems (PEMS). These systems eventually evolved into the equipment that WVU used in the Volkswagen testing to collect a continuous stream of vehicle data including pollutant emission rates, velocity, exhaust flow rate and weather conditions.

“The work has come full circle,” said Kappanna, who is now a calibration specialist at General Motors. “But instead of going back to square one, the challenge is to keep moving the technology forward.”

“As a researcher, you normally don’t get this kind of media attention … our work is well-known among industry and regulators, but this type of notoriety is surprising.” - GREG THOMPSON

A CLEANER FUTURE

On the wall of screens in the WVU media control room, the CNBC video feed showed Pope Francis on his historic visit to the U.S. about to board a plane. Down the hall, Dan Carder sat in a silent studio in front of a single camera awaiting his cue. For him, the momentary pause was a welcome reprieve from the media onslaught. Carder’s phone had not stopped ringing for days and his voice mailbox was full. Suddenly, a voice in his ear monitor told him that as soon as the Pope’s plane left, he would be live on air. Plastered across the screen was a graphic showing that up next was “The Man Who Uncovered Volkswagen’s Lie.”

Reprieve over.

CAFEE has grown to include nine faculty members, five engineers, five technicians and more than 30 graduate students whose research is focused on the study and development of technologies necessary to improve transportation and power systems while working toward a cleaner environment.

They built the largest national database of heavy-duty vehicle exhaust emissions and fuel efficiency data, which is used by the U.S. Department of Energy, the U.S. Department of Transportation and the EPA for air-quality control.

The center pioneered efforts in measuring real-world emissions from mobile sources with PEMS, and now they are ready to introduce a new device that will provide a bridge between real-world vehicle emissions data and health.

AirCom, a device about the size of a large television remote, is a miniature version of PEMS equipment (it’s referred to as micro-PEMS). It is small enough to install on a vehicle’s tailpipe.

Lightweight and inexpensive — with an anticipated cost of a few hundred dollars — compared to the $250,000 price tag of PEMS equipment, AirComs can be installed on a fleet of vehicles.

“You’re looking at the potential to gather a huge amount of incredibly valuable data,” Carder said. “You’ll be able to see concentrations of pollutants in real time, and then be able to make decisions about when and where to drive based on that information.”

Think crowdsourcing for the environmental circuit.

Last year, the White House announced its commitment to the development of “Smart Cities” to help communities build infrastructure to continuously improve the collection, aggregation and use of data to improve the lives of their residents.

AirCom will be a step forward in gathering and spreading out emissions data. The more data they are able to collect, the better air-quality modelers can predict concentrations of air pollution.

“This is an area where we know we can make a difference,” Carder said. “By gathering and connecting this data, we can help cities and the people who live in them. That goes beyond the U.S., too. It’s work that can be applied to global population centers like China and India.”

“I was working in the lab when the news broke … the first phone call I answered was a reporter and she told me I should really check the news. That was when I knew something big was happening.” - DAN CARDER

Soon after news broke of the Volkswagen scandal, media outlets were quick to position, Dan Carder, Greg Thompson, Arvind Thiruvengadam, Marc Besch and Hemanth Kappanna as heroes, champions of the people, who took down a corporate giant. But in many ways — actually, most ways — they are typical engineers who aim to make an impact on people’s lives with their research.

Their lives and work are interdependent — there is no distinction between the two.

In January at the North American International Auto Show in Detroit to collect the “Disruptors of the Year” Shift Award from CNET, the five-member team disappeared inside the Ford exhibit.

Never mind the fact that they were being recognized on the biggest stage in the automotive industry. They were like kids in the shiniest, and most expensive, candy store in the world.

With boyish enthusiasm, the most talked-about engineers in the industry bounced from exhibit to exhibit, admiring engine configurations and technology systems.

“So pretty,” one whispered while fawning over a brake display.

The fraternity among them was unchanged, evidenced by the ceaseless brotherly banter.

Will they ever stop teasing Besch about how long it has taken him to finish his dissertation? Probably not until they’ve seen him through graduation.

In the meantime, they will continue doing what they’ve done for decades — moving technology, emissions research and the industry forward — long after the show lights have dimmed and the glare of the media lens has faded.